SGR mfululizo maji ya joto bomba pampu bidhaa ya jumla

Kampuni yetu ya uzalishaji wa SGR aina mfululizo vertical maji ya joto bomba pampu (hapa chini inaitwa umeme pampu), bomba pampu utekelezaji kiwango JB / T6878-2006, bidhaa mfululizo huu ni mpya umeme pampu iliyoundwa kwa ajili ya bomba shinikizo usafirishaji, kutatua bomba shinikizo chini sana. Kutokana na matumizi ya muhuri ya juu ya mitambo, spindle ya motor imewekwa moja kwa moja, kwa hiyo ufanisi wa juu, kuokoa nguvu, muundo mdogo, ukubwa mdogo, uzito mdogo, upambazaji rahisi na vingine. Na inaweza kutumika kulingana na mahitaji ya lifting na trafiki. Pampu hii ya umeme ina sehemu tatu ya motor ya umeme, muhuri wa mitambo, pampu ya maji, motor ni moja au tatu awamu asynchronous motor; Kuchukua muhuri wa mitambo kati ya pampu ya maji na injini ya umeme, vifaa vya chuma cha kaboni vya ubora wa pampu ya umeme, na baada ya matibabu ya kuvunja kutu kuhakikisha kuwa shaft ina nguvu ya mitambo ya kuaminika zaidi, inaweza kuboresha kwa ufanisi upinzani wa kuvaa na upinzani wa kutu wa shaft, wakati huo huo huo pia kuna matengenezo na kuondolewa kwa urahisi wa shaft, pampu ya kila muhuri wa kumaliza kwa kutumia 'O' mfano wa mpira muhuri kama muhuri utulivu.

SGR mfululizo maji ya joto bomba pampu matumizi

1, mfululizo wa pampu umeme inatumika kwa ajili ya majengo ya juu ya maji ya shinikizo, mviriji bustani, bomba shinikizo, mzunguko wa maji ya baridi na ya joto, usafirishaji wa kioevu cha kuvuka na kioevu cha kutu na aina mbalimbali za usafirishaji wa maji ya boiler, kemikali ya joto, mzunguko wa vifaa vya bomba la mafuta, msaada wa shinikizo.

2, SG aina ya kawaida inafaa kwa ajili ya majengo ya juu ya shinikizo ya kutoa maji, bustani spraying, baridi mnara juu ya maji, mbali kutoa maji, baridi washing, bafuni na nyingine baridi joto maji mzunguko; Matumizi ya joto chini ya 80 ° C.

3, SGR maji ya joto aina inafaa kwa joto la juu maji ya joto shinikizo mzunguko wa joto, boiler na sekta nyingine; Matumizi ya joto chini ya 100 ℃.

SGR mfululizo maji ya joto bomba pampu ya matumizi mbalimbali

1, inafaa kwa ajili ya ulinzi wa mazingira ya mijini, ujenzi, moto, kemikali, dawa, rangi uchapishaji, bia, umeme, electroplating, karatasi, mafuta, migodi, vifaa baridi, nk.

2, inafaa kwa usafirishaji wa maji safi na kioevu kingine na kemikali ya kimwili kama maji safi.

3, kufunga kichwa cha mkono wa shaker, na pia inaweza kuharibu maji angani baada ya kutawanya katika matoto madogo ya mvua kwa spray. Ni mashine nzuri ya shamba, nursery, bustani ya matunda, bustani ya chai.

4, inaweza kutumika pamoja na mfano wowote, vipimo vya chujio cha vyombo vya habari, kutuma sludge kwa chujio kwa chujio cha vyombo vya habari kwa ajili ya aina bora ya pampu ya msaada.

SGR mfululizo maji ya joto bomba pampu matumizi ya hali

1.Import bomba maji shinikizo si zaidi ya 0.3MPa, si chini ya 0.02MPa;

2. ubora wa maji ni maji safi, haipaswi kuwa na fiber au chembe imara, maji ya moto lazima kuwa laini;

Joto la vyombo vya habari: maji baridi si chini ya 0 ℃;

4. joto la mazingira si zaidi ya + 45 ℃;

5. nguvu mzunguko ni 50Hz / 60Hz, voltage ni awamu moja 220V / 240V, awamu tatu ni 380V / 415V / 460V / 660V, voltage kubadilika mbalimbali ni ± 10% ya thamani iliyopimwa.

SGR mfululizo maji ya joto bomba pampu mfano maelezo

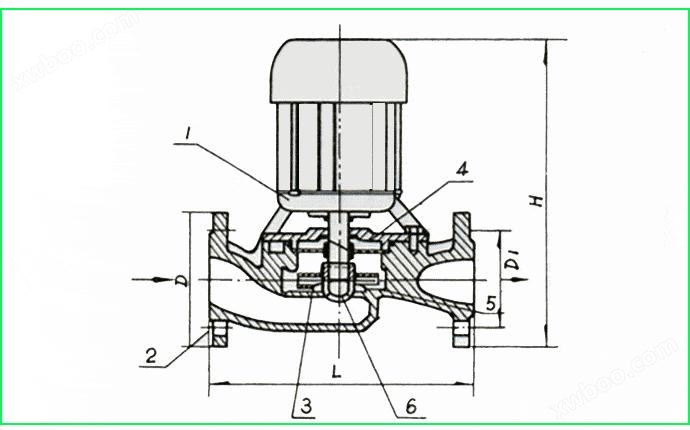

SGR mfululizo maji ya joto bomba pampu muundo chati

SGR mfululizo maji ya joto bomba pampu mifano na utendaji vigezo

| Mfano |

Ukubwa (mm) |

Trafiki (m3/h) |

Yangcheng (m) |

ufanisi (%) |

injini Nguvu (kw) |

Voltage ya (v) |

Synchronization kasi ya (r/min) |

Ufungaji ukubwa kuunganisha flange vyombo vya habari (GB4216-84) viwango viwanda |

uzito (kg) |

|||||||

| L | H | D | D1 | D2 | b | d | (nn) | |||||||||

| SGR25-4-20 | 25 | 4 | 20 | 60 | 0.75 | 220 | 3000 | 270 | 370 | 100 | 75 | 60 | 14 | 12 | 4 | 29 |

| SGR25-3-30 | 25 | 3 | 30 | 60 | 0.75 | 220 | 3000 | 290 | 370 | 100 | 75 | 60 | 14 | 12 | 4 | 30 |

| SGR32-5-20 | 32 | 5 | 20 | 60 | 0.75 | 220 | 3000 | 270 | 380 | 120 | 90 | 70 | 16 | 14 | 4 | 30 |

| SGR40-6-20 | 40 | 6 | 20 | 60 | 0.75 | 220 | 3000 | 270 | 390 | 130 | 100 | 80 | 16 | 14 | 4 | 32 |

| SGR50-10-7.5 | 50 | 10 | 7.5 | 55 | 0.75 | 220 | 3000 | 255 | 390 | 140 | 110 | 90 | 16 | 14 | 4 | 32 |

| SGR50-10-15 | 50 | 10 | 15 | 60 | 0.75 | 220 | 3000 | 270 | 400 | 140 | 110 | 90 | 16 | 14 | 4 |

33 |

| SGR25-4-20 | 25 | 4 | 20 | 60 | 0.75 | 380 | 3000 | 270 | 370 | 100 | 75 | 60 | 14 | 12 | 4 | 29 |

| SGR25-3-30 | 25 | 3 | 30 | 60 | 0.75 | 380 | 3000 | 290 | 370 | 100 | 75 | 60 | 14 | 12 | 4 | 28 |

| SGR25-6.5-30 | 25 | 6.5 | 30 | 60 | 1.5 | 380 | 3000 | 290 | 420 | 100 | 75 | 60 | 14 | 12 | 4 | 37 |

| SGR25-10-50 | 25 | 10 | 50 | 60 | 4 | 380 | 3000 | 350 | 500 | 115 | 85 | 65 | 16 | 14 | 4 | 58 |

| SGR32-5-20 | 32 | 5 | 20 | 60 | 0.75 | 380 | 3000 | 270 | 380 | 120 | 90 | 70 | 16 | 14 | 4 | 28 |

| SGR32-8-30 | 32 | 8 | 30 | 65 | 1.5 | 380 | 3000 | 290 | 420 | 120 | 90 | 70 | 16 | 14 | 4 | 38 |

| SGR32-15-40 | 32 | 15 | 40 | 60 | 4 | 380 | 3000 | 350 | 510 | 135 | 100 | 78 | 18 | 18 | 4 | 60 |

| SGR32-12-50 | 32 | 12 | 50 | 60 | 4 | 380 | 3000 | 350 | 510 | 135 | 100 | 78 | 18 | 18 | 4 | 61 |

| SGR32-14-80 | 32 | 14 | 80 | 60 | 7.5 | 380 | 3000 | 420 | 540 | 130 | 100 | 78 | 18 | 18 | 4 | 98 |

| SGR40-6-20 | 40 | 6 | 20 | 60 | 0.75 | 380 | 3000 | 270 | 390 | 130 | 100 | 80 | 16 | 14 | 4 | 30 |

| SGR40-9-30 | 40 | 9 | 30 | 60 | 1.5 | 380 | 3000 | 290 | 430 | 145 | 110 | 80 | 16 | 14 | 4 | 40 |

| SGR40-18-40 | 40 | 18 | 40 | 60 | 4 | 380 | 3000 | 350 | 520 | 145 | 110 | 85 | 18 | 18 | 4 | 61 |

| SGR40-15-50 | 40 | 15 | 50 | 60 | 4 | 380 | 3000 | 350 | 520 | 145 | 110 | 85 | 18 | 18 | 4 | 62 |

| SGR40-18-65 | 40 | 18 | 65 | 65 | 7.5 | 380 | 3000 | 420 | 550 | 145 | 110 | 85 | 18 | 18 | 4 | 98 |

| SGR40-15-80 | 40 | 15 | 80 | 65 | 7.5 | 380 | 3000 | 420 | 550 | 145 | 110 | 85 | 18 | 18 | 4 | 100 |

| SGR40-15-30 | 40 | 15 | 30 | 65 | 2.2 | 380 | 3000 | 420 | 550 | 145 | 110 | 85 | 18 | 18 | 4 | 100 |

| SGR50-10-7.5 | 50 | 10 | 7.5 | 55 | 0.75 | 380 | 3000 | 225 | 390 | 140 | 110 | 90 | 16 | 14 | 4 | 30 |

| SGR50-10-15 | 50 | 10 | 15 | 60 | 0.75 | 380 | 3000 | 270 | 400 | 140 | 110 | 90 | 16 | 14 | 4 | 31 |

| SGR50-12-25 | 50 | 12 | 25 | 65 | 1.5 | 380 | 3000 | 290 | 430 | 140 | 110 | 90 | 16 | 14 | 4 | 42 |

| SGR50-8-22 | 50 | 8 | 22 | 65 | 1.5 | 380 | 3000 | 290 | 430 | 140 | 110 | 90 | 16 | 14 | 4 | 42 |

| SGR50-15-30 | 50 | 15 | 30 | 65 | 2.2 | 380 | 3000 | 290 | 440 | 160 | 110 | 90 | 16 | 14 | 4 | 45 |

| SGR50-18-40 | 50 | 18 | 40 | 65 | 4 | 380 | 3000 | 350 | 530 | 160 | 125 | 100 | 20 | 18 | 4 | 64 |

| SGR50-16-50 | 50 | 16 | 50 | 65 | 4 | 380 | 3000 | 350 | 530 | 160 | 125 | 100 | 20 | 18 | 4 | 65 |

| SGR50-24-65 | 50 | 24 | 65 | 65 | 7.5 | 380 | 3000 | 420 | 560 | 160 | 125 | 100 | 20 | 18 | 4 | 101 |

| SGR50-20-80 | 50 | 20 | 80 | 65 | 7.5 | 380 | 3000 | 420 | 560 | 160 | 125 | 100 | 20 | 18 | 4 | 102 |

| SGR65-30-15 | 65 | 30 | 15 | 65 | 2.2 | 380 | 3000 | 280 | 450 | 160 | 130 | 110 | 16 | 14 | 4 | 45 |

| SGR65-30-27 | 65 | 30 | 27 | 65 | 4 | 380 | 3000 | 310 | 540 | 160 | 130 | 110 | 16 | 14 | 4 | 68 |

| SGR65-40-40 | 65 | 40 | 40 | 65 | 7.5 | 380 | 3000 | 360 | 570 | 180 | 145 | 120 | 20 | 18 | 4 | 103 |

| SGR65-30-50 | 65 | 30 | 50 | 65 | 7.5 | 380 | 3000 | 360 | 570 | 180 | 145 | 120 | 20 | 18 | 4 | 105 |

| SGR80-35-20 | 80 | 35 | 20 | 65 | 4 | 380 | 3000 | 310 | 560 | 185 | 150 | 125 | 18 | 18 | 4 | 70 |

| SGR80-50-30 | 80 | 50 | 30 | 65 | 7.5 | 380 | 3000 | 340 | 590 | 185 | 150 | 125 | 18 | 18 | 4 | 110 |

| SGR100-40-18 | 100 | 40 | 18 | 65 | 4 | 380 | 3000 | 310 | 570 | 205 | 170 | 145 | 18 | 18 | 4 | 75 |

| SGR100-50-30 | 100 | 50 | 30 | 65 | 7.5 | 380 | 3000 | 340 | 600 | 205 | 170 | |||||